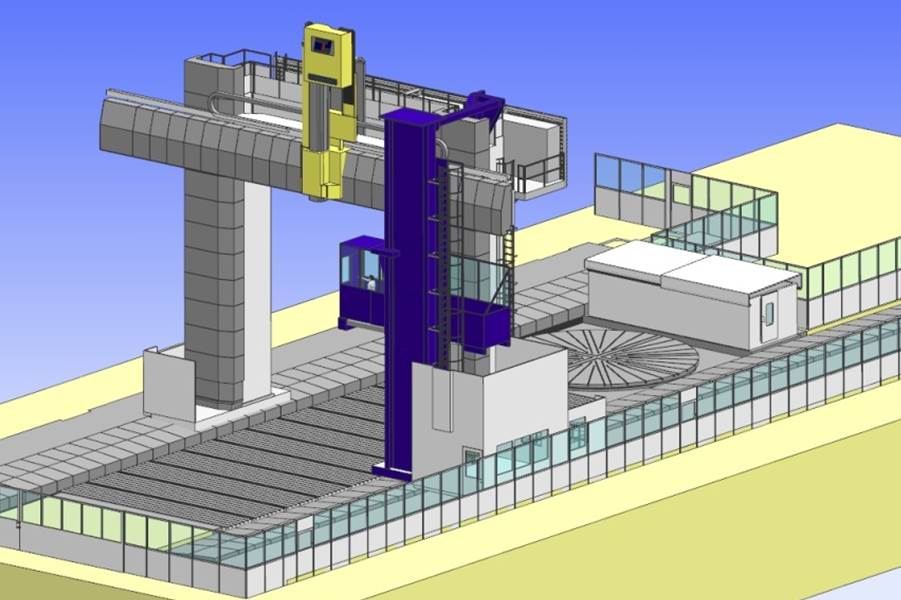

WALDRICH COBURG PORTAL-TYPE MACHINING CENTER

PowerTec 10000 AG-S20/NC – 105kW – Gantry-Design

TECHNICAL DATA

Main dimensions

Total length: 50.000 mm

Total width: 22.500 mm

Total height: 17.500 mm

Clearance width: 10.000 mm

Clearance height: 10.200 mm

Milling and Turning Head S20/NC

Milling Power: 105 kW

Max. speed: 2.500 rpm

Cross-section of ram: 680 x 630 mm

NC-C- axis integrated: n x 360 deg.

Continous contouring

Travels Axes CNC

Portal, longitudinal (X-axis): 35.000 mm

Head, horizontal (Y-axis): 12.000 mm

Ram, vertical (Z-axis): 4.000 mm

Crossrail, vertical (W-axis): 7.500 mm

Rotating axis (C-axis): n x 360 deg.

Universal spindel unit (B-Axis): +/- 95 deg.

Turn-Table axis mode (C20-Axis): n x 360 deg.

Floorplate

Setup width: 8.500 mm

Setup length: 23.750 mm

Load capacity: 25.000 kg/m2

Maximum turning diameter:

11.000 (internal) x 14.000 (external) mm

Turntable

Diameter: 8.000 mm

Load capacity: 400.000 kg

Max. Power: 200 kW

Max. Speed: 38 rpm

Max. Torque: 560.000 Nm

40 kW NC-Universal spindle unit GSC 200 C |

105 kW Vertical spindle unit VSO 200 C |

105 kW Horizontal spindle unit HS 800 C |

| Turning tool holders | |

|---|---|

|

|

| Modular tools | Shank-type tools |

Automatic pick-up area for tools and spindle units

Internal and external coolant supply

Chip conveyor system

Operator‘s platform

Numerical control Siemens Sinumerik 840 D sl

The machine is supported by 109 bored piles of 800 mm of diameter each; for its construction over 674 tons of steel bars, 6,700 cubic meters of concrete and about 600 tons of steel structures for the coverage have been used.

Construction activities at Walter Tosto were carried out not only by the internal technical and operative staff of the Italian company, but also with the support of five technicians of Waldrich Coburg, who managed, on-site, all the necessary steps to put the machine into operation, from assembly to testing.

The largest milling machine ever constructed by Waldrich will allow Walter Tosto to produce increasingly complex and sophisticated items, which manufacturing, was considered unimaginable a short time ago. A tool that will enable the company to achieve new and important opportunities.

Such a facility will allow to open up new scenarios for the manufacturing of oversized steel products.